Saturday, August 25, 2007

air-water-are-examples-of-newtonian-fluids

A substance which undergoes continuous deformation when subjected to a shear stress.

A fluid substance; a body whose particles move easily among themselves.

Fluid is a generic term, including liquids and gases as species.

Water, air, and steam are fluids-->Newtonian Fluid

The resistance to deformation offered by a fluid under a shear stress is called fluid viscosity. This is an important parameter to categorize the various types of fluids, or fluid models (for Fluid Mechanics calculations). The simplest fluid model is the perfect or ideal fluid. This model corresponds to a hypothetical gas or liquid that offers no resistance to shear, and thus has zero viscosity (an inviscid fluid). This model is sometimes used for real fluids with low viscosity.

Ideal Fluid (Perfect or inviscid fluid) - Hypothetical gas or liquid with zero viscosity

Newtonian Fluid - Fluid with a constant viscosity at a fixed temperature and pressure

Non-Newtonian Fluid - Viscosity is a function of shear stress

simulation-proposal-experiment

airflow: from 8in, 1out [i have been done] --> 8in, 6out [prepare Geometry in Full scale]

particleflow: from 8in, 1out [about today, just start, by better view] --> 8in, 6out [prepare Geometry in Full scale]

...WRITING PROPOSAL [REVISED Ed.1]...

Have to write my report up to today...

...EXPERIMENTAL MEASUREMENT PREPARATION...

V, T: ready to measure

C: need to prepare

...2007.25.08...

Sunday, June 24, 2007

3ddp-solver

parameter u.r of momentum and pressure by default...

results:

after iteration 9 AMG Solver still serro...

according to the cfdfluent.com (discussion) says that need to use u.r one by one .... still don't have pattern or formula how to set the discretization methods....

parameter u.r of momentum and pressure by momentum=0.39 and pressure=0.31...

after iteration 4139 error AMG solver...

parameter u.r of momentum and pressure by momentum=0.39 and pressure=0.61...

after iteration 1 error AMG solver...

parameter u.r of momentum and pressure by momentum=0.61 and pressure=0.39...

after iteration 937 error AMG solver...

so try about BC's of the Simulation.....

Saturday, June 23, 2007

equisize-skew->-0.97

May have to re-fine meshing of the geometry...by:

*. coarse mesh then if need more fine mesh have to try methods below...

Because Meshing in GAMBIT automatically generated mesh (especially in 3-D) in most cases, can not provide uniformly high quality in un-structured mesh (hexahedral or tetrahedral) for complex geometry.

On the surface, the unstructured mesh does have advantages to cover large areas of complex geometry, but, in reality, a high quality mesh is always hard to obtain.

One says that need to go back to the blocking of the geometry (meshing process): to divide the geometry into smaller pieces and re-create the surface geometry so that can avoid the highly skewed cells.

**. have to try long iteration until 10^-6 criterion meet.... (already done, but still not convergence)....

have to try one by one....

And .... just an information from CFD source: it must take more time in Meshing Process and Convergence Process......

Friday, June 22, 2007

Under-relaxation-momentum

Error: AMG Solver ...temperature

Solution:

* by Modification of Under-relaxation of Momentum become less than default (0.7) have to try become 0.6....or: 0.5, 0.4, 0.3, 0.35, 0.39....

for 0.5: 500iteration success but after iteration 701 error AMG Solver again...

for 0.4: error after iteration 1185...

for 0.3: error afater iteration 359...

for 0.35: error after iteration 763...

for 0.39: error after iteration 1750...

for 0.396 or 0.389: have to simulate beside check about Meshing or Coupled Solver and not Segregated...

for 0.396: error after iteration 197...

for 0.389: error after iteration 857...

for 0.37: error after iteration 456...

So, want to check it up of coupled...

conclution for u.r. of momentum is about=0.39 and for pressure is about=0.3

but ok before fixed it...need to set the under-relaxation of Pressure....the default is 0.3 but i have to try the 0.28, 0.29 and 0.32 to know influence of this value...

for this use the same convergence criteria that is 1.0e-06 for all graphics...

for 0.28: error after iteration 1086...

for 0.29: error after iteration 264...

for 0.3: error after iteration 1750...already done

for 0.31: error after iteration 2229...

for 0.32: error after iteration 838...

So, the best configuration based-on under-relaxation of pressure and momentum is 0.31 and 0.39 for this case eventhough it's still has error in AMG solver: temperature.

Now, before try coupled solver....need to try to change the the BC's becouse one says that AMG solver and Reversed flow come from settings in BC's....

AMG-Solver-Temperature

Error: divergence detected in AMG solver: temperature

Error Object: ()

Is it about computer?

One suggest me to:

*Make sure about Under-Relaxation:.....I have to try to do it....

*the message indicates that doing something wrong in settign up the case (boundary conditions)...

*Make up Coupled Solver.

*check about mesh.

I have to do it....hope fully it become succeesfull

About the reversed flow pressure outlet.....please to make sure about the BCs and ICs...Because: In fact (real conditions), there should be no backflow at the pressure outlet in the converged solution. But, backflow occurs during the iteration. If so what should I do?

Thursday, June 21, 2007

8-possibilities-meshing-process

HEX MAP None 0.6 NA ERROR: Entity V.5 can not be mesh on lower entity f.79

0.15 NA f.77

0.1; 1.0; 1.0 NA f.75; f68; f67

Hex

Sub map

NA 1.0; 0.6 NA F67; F62

hex Tet primitive NA 0.6 NA Connectivity for v.5 does not allow meshing using the tetrahedral primitive scheme

hex cooper NA 0.6; 1.0 F.63; 67; 68; 69 = all from 4th ventilating lids F38, 37, 57, 5, 42, 53, 24, 22 is Not appropriate for use as a face to project along. Either it is not sub mapped or the choice of source faces is incorrect

HEX STAIRSTEP NA 1.0; 0.6; 2.0 NA Successfully meshed V.5. Created faceted volume (s). F_volume.6 with mesh volumes = 5564

HEX/wedge cooper NA 0.6 NA F38, 37, 57, 5, 42, 53, 24, 22 is Not appropriate for use as a face to project along. Either it is not sub mapped or the choice of source faces is incorrect

Tet/hybrid hexcore NA 0.6 NA Mesh generated for v.5: mesh volumes = 47457. Contains 16 highly skewed element (EQUISIZE SKEW > 0.97)

Tet/hybrid tgrid na 0.6 NA Mesh generated for v.5: mesh volumes = 51780. Contains 11 highly skewed element (EQUISIZE SKEW > 0.97)

There are three meshing process that success for the geometry....

[1]. Stairstep =mesh volume=5,564.

[2]. Tgrid =mesh volume=51,780.

[3]. Hexcore =mesh volume=47,457.

Wednesday, June 20, 2007

Meshing-Process

reversed-flow

reversed flow in 8 faces on pressure-outlet 9.

reversed flow in 9 faces on pressure-outlet 13.

6009 3.3860e-04 1.7957e-01 3.4764e-01 1.9047e-01 5.7751e-04 0:00:00 0

why not displayed word "CONVERGENCE" in the monitor (althought the simulation already done for 1000 iteration = 13minutes and 33seconds --> 81 minutes and 3 seconds)?

[Check the CONVERGENCE status……….by:]

1. Compute from: no need to set… (because already set from geometry by GAMBIT)

2. Solve-Control-Solution—Under-relaxation

Solve-Control-Solution—Pressure-Velocity Coupling

Solve-Control-Solution—Discretization; or

3. Solve-Monitor-Residual--Convergence Criteria; or

4. Meshing process about Equisize SKEW > 0.97 (11, 16 or … by Tet/Hybrid- TGrid and Hexcore

:-)smile

divergence-in-AMG-solver

...

reversed flow in 23 faces on pressure-outlet 4.

reversed flow in 31 faces on pressure-outlet 5.

reversed flow in 35 faces on pressure-outlet 6.

reversed flow in 38 faces on pressure-outlet 7.

reversed flow in 52 faces on pressure-outlet 8.

reversed flow in 8 faces on pressure-outlet 9.

reversed flow in 8 faces on pressure-outlet 13.

Error: divergence detected in AMG solver: temperature

Error Object: ()

why?.....how to fixed it?.....

solution for that error: in windows of FLUENT click SOLVE then click Initialize-Initialize-set Velocity Magnitude = 1 or other values then click Reset-Apply-Close.

Another solution is to click Initialize-Initialize- then click Init...

...continuousimprovement of lasmanp's thesis...

Saturday, June 16, 2007

Holman1992-Natural-Convection-System

The movement of the fluid in free convection, wheter it is a gas or liquid, results from the bouyancy forces imposed on the fluid when its density in the proximity of the heat-transfer surface is decreased as a result of the heating process.

The bouyancy forces would not be present if the fluid were not acted upon by some external force field such as gravity, although gravity is not only type of force field which can produce the free-convection currents; a fluid enclosed in a rotating machine is acted upon by a centrifugasl force field, and thus could experince free-convection currents if one or more of the surfaces in contact with the fluid were heated.

The bouyancy forces which give rise to the free-convection currents are called body forces.

Thursday, June 14, 2007

heat-flux

Friday, June 8, 2007

Leonhard-Euler-Wikiedia

Madsen,2006-use-eulerian-model

The governing equations of the multi-fluid model can be derived by conditionally ensemble averaging of the local instant conservation equation of single-phase flow (Drew, 1983; Drew and Passman, 1999). In the Madsen, J., (2006) thesis the flow assumed to be isothermal; hence, energy balances are not needed. Furthermore, there is no interfacial mass transfer between the gas and particle phases.

Monday, June 4, 2007

turbulence-model-for-each-phase

+*is appropriate choice when the turbulence transfer among the phases plays a dominant role.

+*Turbulence predictions are obtained from two long equations which both of that equations have two terms that must be approximated like these:

* Clq = 2,

* Cql = 2ηlq/(1+ηlq).

where: ηlq is the ratio of the characteristic particle relaxation time and the Lagrangian integral time scale of the phases q and l.

+*The turbulent viscosity defined as a equations.

Recomended for the thesis (1st priority), and use LAUNDER and SPALDING (1974), because so famous used by researchers like Lu and Howatrh (1996a, 1996b). Although we can use in simulation as 2nd priority,dispersed t. m. or mixture t. m. as the 3rd priority for these works.

dispersed-turbulence-model

Turbulence in the continuous phase is described by:

- a modified k-ε model,

- the influence of the dispersed phase on the continuous phase q, and

- the production of turbulent kinetic energy

- For the turbulence quantities of the dispersed phase user can use Mr. 'X' approach (for e.g. Muehlbauer, P 2004 use Simonin, Viollet (1990) approach).

Think that 1st phase=gas, air, and 2nd phase=particles, water,

mixture-turbulence-model

using mixture properties and mixture velocities is sufficient to capture important features

of the turbulent flow. There are 5th equation for modeling turbulence in this mixture turbulence model, i.e.:

- ske-2 eqn

- mixture density

- mixture velocity

- the turbulent viscosity

- the production of turbulence kinetic energy

Sunday, June 3, 2007

Sohn, et. al. 2004-using-CFD

temperature, pressure, turbulence, and contaminant concentrations are calculated

by solving the governing partial differential equations for fluid flow, heat

transfer, and conservation of species. These differential equations describe a threedimensional

viscous fluid flow field. Due to the non-linearity of these equations,

they cannot be solved analytically. The CFD approach is to transform these differential

equations into a set of discrete algebraic equations and solve the algebraic

equations by an iterative procedure.

Researchers have used CFD since the early 1970s. Its use has increased dramatically

in the last decade as a result of advances in the computing power. In the

1980s, Cray supercomputers typically were used to process CFD simulations, with

solution times taking days (which followed a long wait to even gain access to use the

supercomputer). The same simulations may now be run on a personal laptop computer

in a matter of hours. CFD modeling has been continually validated since its

inception against many known fluid phenomena. It is considered a very useful tool

for engineers and scientists working on fluid flow problems across many disciplines.

Saturday, June 2, 2007

Muehlbauer, et. al., 2001-future-needs-on-CFD

CFD-Packages-in-the-market

[Examples of CFD Models for flow around buildings are: Dynaflow, FEM3C, GASFLOW, HIGRAD, and TEMPEST.

Examples of building Interior Flow and Transport Models are: COMIS, MIAQ4, CONVECT9, GASFLOW.

Examples of Mesoscale Atmospheric Models are: COAMPS, HOTMAC, NORAPS, RAMS.

Examples of Plume Dispersion Models are: ADPIC, HYPACT, LODI, RAPTAD, SALB.

Examples of Subway system & Interior flow models: GASFLOW, SES.]

[2]. Sohn, et. al. (2004) already reviewed many existing technologies that could protect the supply air systems of buildings from chemical/ biological (chem/bio) contaminants such as FEM3MP, HPOC, CONTAM, dan FLOVENT. FEM3MP and HPOC for external dispersion modeling, CONTAM and FLOVENT for internal dispersion modeling. The results provide a modeling approach that can be used to simulate the dispersion of contaminants inside buildings. Such a numerical simulation will help designers and managers evaluate possible ways to reduce occupant exposures to chem/bio contaminants.

[M]odeling Package Name: FLOVENT

[A]uthor: Flomerics Incorporated)

[N]umerical Simulation Description: CFD - Specific to the built environment(internal/external flows)

[M] Airpack

[A] FLUENT Incorporated

[N] CFD - Specific to the built environment (internal/external flows)

[M] STAR-CFD

[A] Adapco Group

[N] CFD - Multi-purpose code

[M] CFX

[A] ANSYS

[N] CFD - Multi-purpose code

CONTAM 2.1

National Institute of Science and Technology (NIST)

Nodal Analysis - Multizone indoor air quality and contaminant transport analysis.

IAQX (MIAQ4) (Nazaroff and Cass, 1989)

EPA

Add on to RISK for particulate, sources, spills

COMIS (Festel, 1999)

LBNL

Conjunction of Multizone Infiltration Specialists

Integration of CFD and COMIS (Sohn, et. al., 2006)

LBNL

Current research area for LBNL Airflow and Pollutant Transport Group

[3]. CFD is a mathematical modeling procedure whereby the fluid parameters of velocity, temperature, pressure, turbulence, and contaminant concentrations are calculated by solving the governing partial differential equations for fluid flow, heat transfer, and conservation of species. These differential equations describe a threedimensional viscous fluid flow field. Due to the non-linearity of these equations, they cannot be solved analytically. The CFD approach is to transform these differential equations into a set of discrete algebraic equations and solve the algebraic equations by an iterative procedure.

[4]. This thesis is about internal dispersion,... and have two fluid flow i.e.: particle and gas.

[5]. STAR-CFD, CFX dan FLUENT in two phase modeling.

[6] Sippola and Nazaroff (2002), describe four broad methods of predicting particle deposition rates that found in the literature: empirical equations, Eulerian models, sublayer models and Lagrangian simulations. These methods usually require information about the particle size and density, as well as the air speed and dimensions of the duct containing the flow. Deposition rates are most commonly reported in the form of the dimensionless deposition velocity, Vd+, versus the dimensionless relaxation time, τ+, a measure of particle inertia.

...[to be continued]...

Hinds1999-characteristic-of-particles

Thursday, May 31, 2007

Monday, May 28, 2007

Convection-Fluent-Thesis

-Heat energy transferred between a surface and a moving fluid at different temperatures is known as convection.

#the default operating temperature is setting under Boussinesq Parameters.

#it is tempting to specify an operating density here too, but the help panels say that it is not necessary to specify operating density when using the Boussinesq approximation.

Coulombic force - definition

early-

Verify the result.

great idea, lasman

Zang and Ahmadi (2000)-

Particle transport and deposition play a major role in filtration, combustion, air and water pollution, coal transport and cleaning, microcontamination control, xerography, and many other industrial processes.

For trajectory analysis of aerosol particle transport and deposition in vertical and horizontal turbulent duct flows, Zang and Ahmadi (2000) used a particle equation of motion including:

- -Stokes drag,

- -Brownian diffusion,

- -Lift force, and

- -Gravitational forces

Result Simulation agree with Experiment: The lift and drag forces play a dominant role in particle transportation and deposition.

The Brownian force significantly affects the dispersion of submicrometre particles.

Gravity affects the particle deposition process in a vertical duct through the lift force and through direct sedimentation in a horizontal duct.

Garrick, et al., 2006-FLUENT-balance-on

Sunday, May 27, 2007

Proposal

2. Objectives

3. Scopes

4. Theory: Particles Dynamics

5. Research Methodology

6. Boundary conditions

7. Research Procedures

8. References

9. Appendixes

"Modified can only a little bit"

Saturday, May 26, 2007

GRC2007-SolidMecahanics-FluidStatics-FluidDynamics

The conservation of mass is a fundamental concept of physics along with the conservation of energy and the conservation of momentum. Within some problem domain, the amount of mass remains constant--mass is neither created nor destroyed. This seems quite obvious, as long as we are not talking about black holes or very exotic physics problems. The mass of any object can be determined by multiplying the volume of the object by the density of the object. When we move a solid object, as shown at the top of the slide, the object retains its shape, density, and volume. The mass of the object, therefore, remains a constant between state "a" and state "b."

Fluid Statics

In the center of the figure, we consider an amount of a static fluid , liquid or gas. If we change the fluid from some state "a" to another state "b" and allow it to come to rest, we find that, unlike a solid, a fluid may change its shape. The amount of fluid, however, remains the same. We can calculate the amount of fluid by multiplying the density times the volume. Since the mass remains constant, the product of the density and volume also remains constant. (If the density remains constant, the volume also remains constant.) The shape can change, but the mass remains the same.

Fluid Dynamics

Finally, at the bottom of the slide, we consider the changes for a fluid that is moving through our domain. There is no accumulation or depletion of mass, so mass is conserved within the domain. Since the fluid is moving, defining the amount of mass gets a little tricky. Let's consider an amount of fluid that passes through point "a" of our domain in some amount of time t. If the fluid passes through an area A at velocity V, we can define the volume Vol to be:

Vol = A * V * t

A units check gives area x length/time x time = area x length = volume. Thus the mass at point "a" ma is simply density r times the volume at "a".

ma = (r * A * V * t)a

If we compare the flow through another point in the domain, point "b," for the same amount of time t, we find the mass at "b" mb to be the density times the velocity times the area times the time at "b":

mb = (r * A * V * t)b

From the conservation of mass, these two masses are the same and since the times are the same, we can eliminate the time dependence.

(r * A * V)a = (r * A * V)b

or

r * A * V = constant

The conservation of mass gives us an easy way to determine the velocity of flow in a tube if the density is constant. If we can determine (or set) the velocity at some known area, the equation tells us the value of velocity for any other area. In our animation, the area of "b" is one half the area of "a." Therefore, the velocity at "b" must be twice the velocity at "a." If we desire a certain velocity in a tube, we can determine the area necessary to obtain that velocity. This information is used in the design of wind tunnels. The quantity density times area times velocity has the dimensions of mass/time and is called the mass flow rate. This quantity is an important parameter in determining the thrust produced by a propulsion system. As the speed of the flow approaches the speed of sound the density of the flow is no longer a constant and we must then use a compressible form of the mass flow rate equation. The conservation of mass equation also occurs in a differential form as part of the Navier-Stokes equations of fluid flow.

Reprint On Line: from Glenn Research Center 2007

CFD-FLUENT-Multiphase-Eulerian-Model

The Eulerian model solves a set of n energy, momentum and continuity equations for each phase. Coupling is achieved through the pressure and interphase exchange coefficients. Particle tracking (using the Lagrangian dispersed phase model) interacts only with the primary phase. Compressible flow and species transport and reactions are not allowed when using the FLUENT 6.1 Eulerian model [more about the limitation of Eulerian model].

The equations being solved in the Eulerian model are as follows:

1. Continuity equation (void fraction equation) for the q-th phase from total of n phases

2. Momentum equation for the q-the phase

3. Conservation of energy of the qth phase

1. Continuity equation (void fraction equation) for the q-th phase from total of n phases

Properties of Continuity equation:

- the volume fraction of the q-th phase,

- the mass transfer from the p-th to q-th phase.

A similar term appears also in the momentum and enthalpy equations.

The term is zero by default, but can be specified either as a constant, or by a user-defined function (UDF).

2. Momentum equation for the q-the phase

Properties of Continuity equation:

- the qth phase stress-strain tensor equation

- the interphase momentum exchange coefficient (expressed in symmetric form)

- f=CD*Re/24 (Re=Reynold number)

- CD is the drag coefficient or drag factor

# for Re>1000, the drag factor = 0.44

# for other values of Re, the drag factor = (24/Re)*(1+0.15Re^0.687)

- Relative Reynolds number for primary phase, q and secondary phase, p.

- Relative Reynolds number for secondary phase, p and r.

- viscosity of a mixture of phases p and r,

- the diameter of droplets or bubbles of the phase p,

- the diameter of droplets or bubbles of the phase p and r,

- the interphase momentum exchange coefficient (expressed in General form equations(FLUENT)) include:

# a drag function,

# a “particulate relaxation time”,

# an external body force,

# a lift force, and

# a virtual mass force.

3. Conservation of energy of the qth phase

Properties of Conservation of Energy:

- the specific enthalpy of the qth phase

- the heat flux

- a source term that includes sources of enthalpy (e.g. chemical reaction or radiation)

- the intensity of heat exchange between the p-th and q-th phases

- the interphase enthalpy (e.g. the enthalpy of the vapour at the temperature of the droplets, in the case of evaporation).

- The heat transfer coefficient between the p-th and q-th phases is related to the p-th

phase Nusselt number

- the Nusselt number for fluid-fluid multiphase is determined from the Ranz and

Marshall (1952, 1952a) correlation: Nup = 2.0 + 0.6*Rep^(1/2)*Pr^(1/3)

- the q-th phase Prandtl number

factors-affecting-particles-movement

Want to divide the problem into two big simulation:

1. AF_Only: Simulation of Airflow

2. AP_Only: Simulation of Multiphase flow (Particle and Gas Phases)

Governing Equations is Convective-Diffusion or GDE Equation.

Friday, May 25, 2007

Mathworld-Wiki-bc(s)-in-the-solution-of-O&P-DEs

1. Dirichlet boundary conditions specify the value of the function on a surface .

Dirichlet bc(s) is PDE boundary conditions which give the value of the function on a surface, e.g., T=f(r,t).

In mathematics, a Dirichlet boundary condition (often referred to as a first-type boundary condition) imposed on an ODE or a PDE specifies the values a solution is to take on the boundary of the domain. The question of finding solutions to such equations is known as the Dirichlet problem.

In the case of an ODE such as: d2y/dx2 + 3y = 1on the interval [0,1] the Dirichlet boundary conditions take the formy(0) = α1 y(1) = α2 where α1 and α2 are given numbers.

For a PDE on a domain Ω C Rn such as: Δy + y = 0 (Δ denotes the Laplacian), the Dirichlet boundary condition takes the formy(x) = f(x) all x C ∂Ωwhere f is a known function defined on the boundary ∂Ω.

Dirichlet boundary conditions are perhaps the easiest to understand but there are many other conditions possible.

2. Neumann boundary conditions specify the normal derivative of the function on a surface,

Neumann bc(s)s is PDE boundary conditions which give the normal derivative on a surface.

In mathematics, a Neumann boundary condition (named after Carl Neumann) imposed on an ODE or a PDE specifies the values the derivative of a solution is to take on the boundary of the domain.

In the case of an ordinary differential equation, for example such as

d2y/dx2 + 3y = 1

on the interval [0,1], the Neumann boundary condition takes the form

dy(0)/dx=α1

dy(1)/dx=α2

where α1 and α2 are given numbers.

For a partial differential equation on a domain

Ω C Rn

for example : Δ2 y +y =0 (Δ2 denotes the Laplacian), the Neumann boundary condition takes the form: dy(x)/dv = f(x), all x E ∂Ω

Here, 'del' denotes the (typically exterior) normal to the boundary ∂Ω and f is a given scalar function. The normal derivative which shows up on the left-hand side is defined as

dy(x)/dv = ∇ y(x) dot v(x)

where ∇ is the gradient and the dot is the inner product.

3. Cauchy boundary conditions specify a weighted average of first and second kinds.

Bc(s) of a PDE which are a weighted arithmetic mean of Dirichlet boundary conditions (which specify the value of the function on a surface) and Neumann boundary conditions (which specify the normal derivative of the function on a surface).

4. Robin boundary conditions.Bc(s) of a PDE which, for an elliptic PDE in a region R, Robin bc(s) specify the sum of alpha*u and the normal derivative of u = f at all points of the boundary of R, with alpha and u being prescribed.

Robin boundary condition is another type of hybrid boundary condition; it is a linear combination of Dirichlet and Neumann boundary conditions.

5. Mixed boundary conditions.

In mathematics, a mixed boundary condition for a PDE indicates that different boundary conditions are used on different parts of the boundary of the domain of the equation.

For example, if u is a solution to a PDE on a set Ω with piecewise-smooth boundary and is divided into two parts, Γ1 and Γ2, one can use a Dirichlet boundary condition on Γ1 and a Neumann boundary condition on Γ2,

u for Γ1 = u0

∂u/∂n for Γ2 = g

where u0 and g are given functions defined on those portions of the boundary.

physical-properties-gas-particles

- fluid air and particle

- properties from FLUENT

FEATURE : Air -- Particle

Density (kg/m3) : 1.1777 -- 996.54

Cp (j/kg-K) : 1006.43 -- 4182

Thermal Conductivity (w/m-K) : 0.0242 -- 0.6

Viscosity (kg/m.s) : 1.7894e-05 -- 0.001003

Molecular weight (kg/kgmol) : 28.966 -- 18.0152

Standard State Enthalpy (j/kgmol) : 0 -- 0

Reference Temperature (K) : 299.86 – 299.86

Thermal Expansion Coefficient (1/K): 0.003.3495 – 0.0002754

à (here: italic) =set by user as FREE Convection (Boussinesq Parameters)

4-bc's-from-Lu and Howarth (1996)

2.No-slip condition at the solid wall is applied for velocities.

3.”Wall-functions’ are applied to describe the turbulent flow properties in near wall regions.

4.Neumann Boundary Conditions are applied at the outlet to satisfy the mass conservation law.

5.The most important information for particle transport is the initial conditions and physical state of the paticles.

Hartle2005-seven-limitation-of-Eulerian-in-FLUENT

1. Only Κ−ε turbulence models are allowed

2. Particle tracking works with the primary phase only

3. Translationallyperiodic flow (either specified mass flow rate or specified pressure drop) not allowed (annular sectors)

4. Compressible/inviscidflow not allowed

5. Phase change (Melting/Solidification) not allowed

6. Species transport not available

7. Heat transfer not available

Thursday, May 24, 2007

CFD: Tools of Aerosol Particle Transport Model

Most previous CFD analyses have been concentrated on simulating the airflow patterns and heat and mass transfer between zones..

Only a few numerical studies of aerosol particle deposition and distribution in multi-zone areas have been found to date.

It is necessary to use CFD methods to investigate the air movement and aerosol particle deposition and migration in a full-scale multi-zone ventilation system.

airflow pattern in free convection

It is known that the airflow pattern plays a fundamental role in the deposition, migration and distribution of aerosol particles in the multi-zone area.

The study of such situations has been carried out both by experimental measurements and by numerical studies.

Generally speaking from the experimental and numerical studies, experimental study can supply direct knowledge of airflow and particle deposition in the ventilated space based on the measurement data on sample points. However, it is found that experimental study cannot provide enough information about the air movement and particle deposition and distribution in the whole area due to the limited number of measurement points.

gravity-effects-for-every-particles-size-in-indoor-environment

*larger particles (particle size dp > 4 micron) will deposit on internal surfaces quickly under the influence of gravity,

*particles which are less than 2 micron may become aerosol particles and remain suspended in the air and the occupied spaces in which particle molecular diffusion and air movement dominate the particles’ movement and the gravitational force becomes less important.

*Particles which are between 2 and 4 micron may settle down on the interior surfaces or remain suspended in the air, which is mainly influenced by both the airflow pattern and gravity.

Particles which are suspended in the air have a significant influence on human health and the indoor air quality (IAQ). The IAQ in multi-zone buildings has been given much attention in recent years. It is necessary to investigate the airflow pattern and indoor aerosol particle distribution in ventilated multi-zone buildings.

background-IAQ-indoor environment

In WEIZHEN LU* and ANDREW T. HOWARTH*, 1996 reported that Since the energy crisis in 1970, a significant number of buildings have become more airtight in modern industrial countries for the purpose of energy conservation. Many of these buildings are also divided into multi-zone areas. The air exchange between indoors and outdoors is mainly through the ventilation system. In such situations, the indoor air movement and pollutant particle deposition and migration are largely influenced by particle properties, ventilation conditions, room dimensions, sizes and locations of interzonal openings, turbulence intensity, etc.

airtight (m-w.com), adj.:

1 : impermeable to air or nearly so

2 a : having no noticeable weakness, flaw, or loophole

2 b : permitting no opportunity for an opponent to score

The indoor aerosol particles are a combination of indoor sources (e.g. cigarette smoke, building materials, personal products, etc.) and outdoor sources (e.g. car exhaust emissions, coal and oil combustion, pollen, road dust, etc.) which enter the room through ventilation systems.

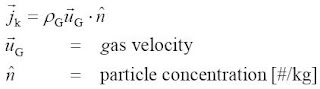

aerosol-particle-dynamics-equations-governing

Wednesday, May 23, 2007

gde-momentofsizedistributionfunction-momentevolutionequation-quadraturesolution

produced, it is important to have detailed knowledge of the physical processes

involved in particle formation, therefore modelling is needed.

Aerosol dynamics is described by an equation termed the general dynamic

equation (GDE) [Friedlander 2000]. This equation gives the evolution in time of

the size distribution function:

n is the number density function,

t the time,

xdot the velocity vector,

u and v are particle volume,

β is the collision frequency function,

J the nucleation rate and

kdep the deposition flux.

Actually, the transport of the nanoscale particles dispersed throughout the fluid is governed by the aerosol general dynamic equation (GDE).

We can't close the problem since we have integrals of functionals which we can't evaluate simply in terms of moments.

objective(s) and scope(s) of thesis

Scope (s) and Objective(s) of Thesis Work

1. CFD Simulation of aerosol concentration in a current RSC.

2. Experimental measurements of source concentration and ambient concentration in the cooperative.

3. CFD Simulation to improve airflow in the cooperative.

4. Experimental measurements to verify the model.

And the Objective of the Research work are:

The research start with finding model that represent aerosol particles transport in the cooperative from source of concentration. FLUENT CFD package with GAMBIT will be used, to perform simulation of airflow in the current smoking cooperative. It will be used to improve the airflow to lessen the risk of workers’ exposure to smoke particle. Experimental verification will be performed.